Pillar Technologies Product Line

Pillar Universal Treater Stations

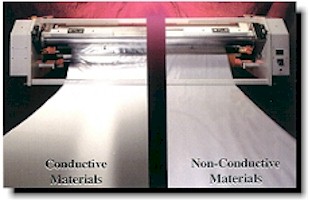

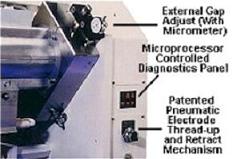

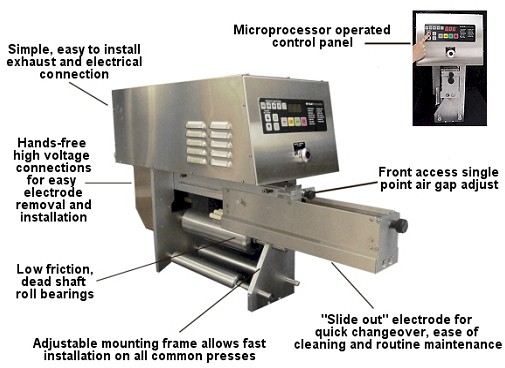

For over 3 decades, Pillar Technologies has provided technical innovations to the packaging and converting industries. Converters can now have the best of both worlds with the introduction of the "Universal" corona surface treating station. This advanced technology features a patented design which allows the flexibility of bare roll with the efficiency of covered roll systems.

For over 3 decades, Pillar Technologies has provided technical innovations to the packaging and converting industries. Converters can now have the best of both worlds with the introduction of the "Universal" corona surface treating station. This advanced technology features a patented design which allows the flexibility of bare roll with the efficiency of covered roll systems.

Patented Modular Interchangeable Electrode Magazine. Electrodes on the "Universal" can be replaced in a matter of seconds. Slide the segmented stainless steel magazine out and the ceramic tube magazine in, now you're ready to run conductive webs. The patented modular magazine approach makes cleaning effortless and downtime minimal.

Patented Modular Interchangeable Electrode Magazine. Electrodes on the "Universal" can be replaced in a matter of seconds. Slide the segmented stainless steel magazine out and the ceramic tube magazine in, now you're ready to run conductive webs. The patented modular magazine approach makes cleaning effortless and downtime minimal.

Universal Corona Treating - Features & Benefits

|

|

|

|

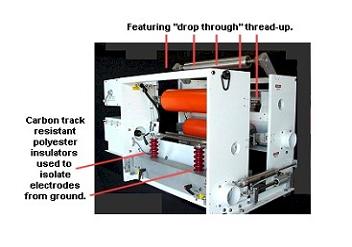

Pillar Split Box Treater Stations

Pillar's Universal Split Box Treater Station for Blown Film Applications

Universal Split Box Corona Treaters - Features & Benefits

|

|

|

|

|

|

Pillar P6000 Power Supplies

Introducing the NEW 5 to 30 kW P6000 Series Power Supply. Backed with over three decades of experience, this system controls the level of power applied to your corona treater. The P6000 Series features the latest in transistorized technology providing the most versatile corona treater power supply on the market today. This compact unit incorporates a circuit design that enables instant and efficient power without the need for excessive switching devices. The P6000 automatically adjusts itself to match into any electrode style or dielectric material. In fact, the P6000 Series offers the operator better than 4 to 1 load matching.

Introducing the NEW 5 to 30 kW P6000 Series Power Supply. Backed with over three decades of experience, this system controls the level of power applied to your corona treater. The P6000 Series features the latest in transistorized technology providing the most versatile corona treater power supply on the market today. This compact unit incorporates a circuit design that enables instant and efficient power without the need for excessive switching devices. The P6000 automatically adjusts itself to match into any electrode style or dielectric material. In fact, the P6000 Series offers the operator better than 4 to 1 load matching.

The versatility of the P6000 Series Corona Treater Power Supply possesses a turn down ratio of 20 to 1, or better, enabling the operator to precisely turn the power up or down to achieve the desired treat level. The specially designed power measurement circuit guarantees that the power specified is the power being delivered. The feedback circuit automatically maintains output power regardless of minor changes in load conditions, such a changes in humidity.

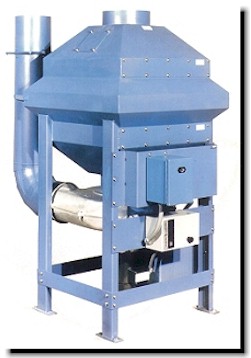

Pillar Ozone Destruct Systems

Pillar's Ozone Destruct Exhaust System

Features

- Durable: Constructed from sturdy, corrosion resistant, aluminized steel.

- Reliable: Homogeneous metal oxide (manganese dioxide) catalyst ensures the efficient destruction of O3 emissions.

Standard Options

- Stainless Steel Construction - increased durability

- Elapsed Time Hour Meter - monitors and displays direct equipment usage time for periodic maintenance.

- Pressure Switch with Alarm Light - monitors pressure drop across the catalyst bed then activates an alarm light when an excessive drop occurs as a result of clogged filters.

- Pressure Switch with Magnahelic Gauge - includes analog style continuous display pressure meter.

Pillar Wide Web Stations

Wide Web Applications - Features & Benefits

- Unique electrode design specifically created for wide web applications: Pillar wide web corona treatment systems provide precision-machined supports at multiple locations for positive structural integrity, minimizing potential for electrode distortion.

Advanced design provides close capture of ozone and superior cooling: Precisely machined electrodes are mounted on an integral exhaust manifold for close capture of ozone and improved cooling across the electrodes. Not only does this unique design minimize ozone contamination into the work environment, it affords additional protection against thermal distortion of the electrode, a softer corona for better treater performance and longer covering life.

Advanced design provides close capture of ozone and superior cooling: Precisely machined electrodes are mounted on an integral exhaust manifold for close capture of ozone and improved cooling across the electrodes. Not only does this unique design minimize ozone contamination into the work environment, it affords additional protection against thermal distortion of the electrode, a softer corona for better treater performance and longer covering life.- Stainless steel jacking screws at each support: Allow fine-tuning adjustment of the air gap across the entire electrode length.

- Supports are slotted to provide for lateral movement of electrodes: Allowing for thermal expansion and eliminating electrode distortion from mechanical contact.

- Faster, easier web threading with Pillar's walk-through web feed design: Easy access through the treater system allows simple web threading by a single operator. A Wide span of electrode retraction makes web thread even easier.

- Shipped pre-assembled for fast, easy turn-key installation: Both the treater station and power supplies are completely pre-assembled, pre-plumbed and pre-wired for immediate installation. The complete, pre-assembled system is thoroughly tested and exhaustively "dry run" before we ship it to you - absolute assurance that it will perform perfectly in your installation. We can even supply mounting pads precisely machined to fit the other equipment in your system. No snags. No bugs. No installation delays, time-wasting trial runs, or "shake-out" time. Pillar's commitment to quality, technologically advanced surface treatment equipment.

Pillar Narrow Web Stations

Pillar's Narrow Web Integrated Treater Station

Pillar's Narrow Web Corona Treating Integrated Power Supply Design

Previous 1 Next